Services / Infrastructure

ARES – Assestment Road Equipment System

ARES – Assessment Road Equipment System, is an innovative system that allows for the analytical assessment and determination of the actual performance of restraint devices along road networks, through surveys with high-performance vehicles, artificial intelligence models, machine learning algorithms, and performance decay curves.

It provides essential support for managing bodies. It is an objective criterion that classifies the activities necessary for the technical control of road efficiency, based on their importance or urgency, and defines a priority index for interventions in the context of optimising available resources.

Through ARES and its specific WebApp, it is possible to equip oneself with a system for the integrated management of restraint systems capable of identifying real critical issues and assessing the priorities of interventions, based on the maintenance status of the device, the characteristics of the support and the surrounding conditions, ensuring the overall safety of the infrastructure and minimising resources and costs.

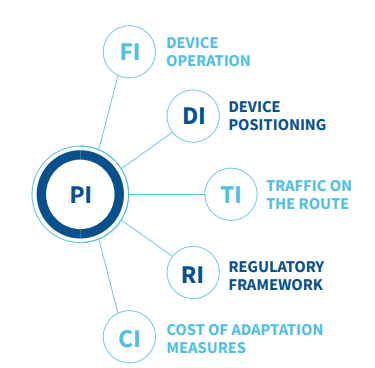

The objective of ARES is to determine a priority index for safety barrier adaptation measures, based on the intrinsic characteristics of the device, its state of maintenance, the characteristics of the support and the surrounding conditions, which characterise the Functioning Index.

For all devices whose Functionality Index is below a predefined acceptability value, adaptation measures must be planned in order to guarantee containment capacity.

For all sections requiring adaptation measures, the priority of intervention is defined taking into account additional parameters such as the location of the device, its intended use, traffic, the regulatory context and cost.

To assess each of these characteristics, specific ‘accessory indices’ were used, correlated with each other according to coefficients that appropriately weigh their relative influence.

Through the survey carried out with a High Performance vehicle, it is possible to define homogeneous sections and identify and register road restraint devices.

- ASSURE the status of the restraint devices installed throughout the network, identify the different types and their respective characteristics, including geometric ones

- ASSESS the geometric conditions of the support

- KNOW the boundary conditions of each device

On-site testing allows for the mechanical characterisation of supports in order to determine the behaviour of safety devices.

By performing dynamic tests, it is possible to determine the characteristics of the ground and its interaction with the device’s upright at the moment of impact. The presence of poor-quality ground or an inadequately shaped embankment effectively reduces the resistance of the restraint device.

By performing pull-out tests, it is possible to determine the characteristics of the concrete support for barriers installed on engineering structures.

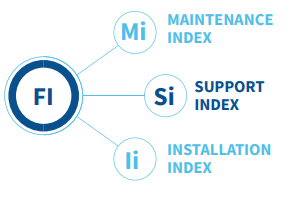

The Functioning Index (FI), which assesses the containment capacity of the device, determines the need for maintenance work. If the Functioning Index falls below a predefined limit value, corrective measures must be taken.

The actual containment capacity depends on:

- Maintenance index Im: intrinsic capacity of the device depending on its condition.

- Support index Is: mechanical characteristics of the support in situ, compared to the characteristics of the support on which the device was crash tested.

- Installation index Ii: grips within critical deformation spaces such as obstacles.

For each index, the decay of the device’s containment energy is evaluated in relation to optimal conditions. The decay curves were evaluated through a series of finite element numerical simulations.

If the Operating Index is lower than a predefined limit value, corrective measures must be taken.

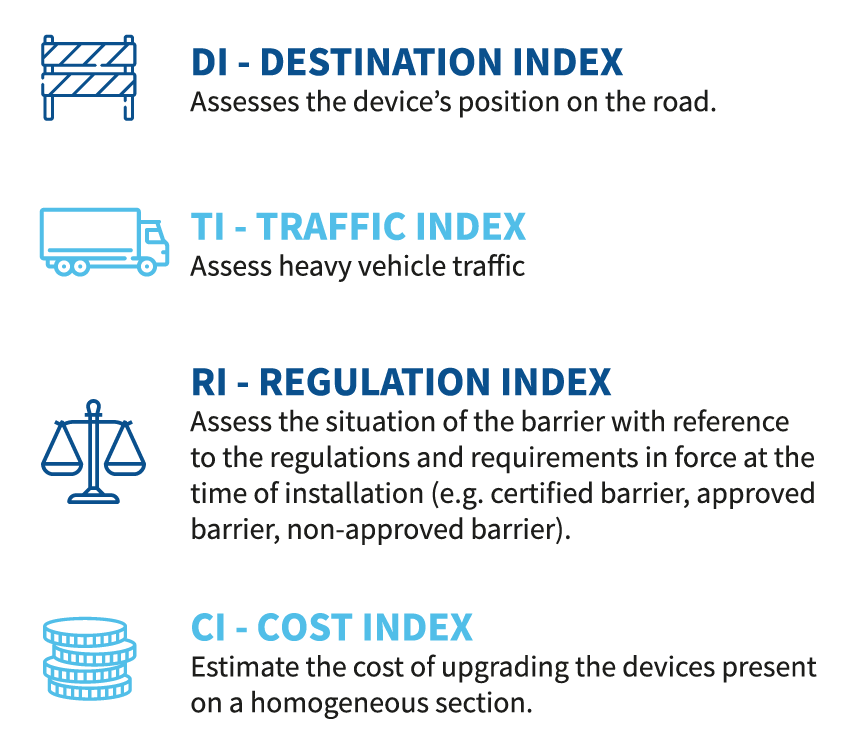

ADDITIONAL INDICES AND CALCULATION OF INTERVENTION PRIORITY

The urgency of an intervention is influenced by the assessment of other indices.

Following the census and on-site tests that enable the calculation of primary and secondary indices, a proprietary algorithm assesses their relative importance, allowing the priority of intervention to be evaluated according to the formula below:

PI = α∙ IF+β∙ ID+ϒ∙ IT+δ ∙ IN + ε∙ IC

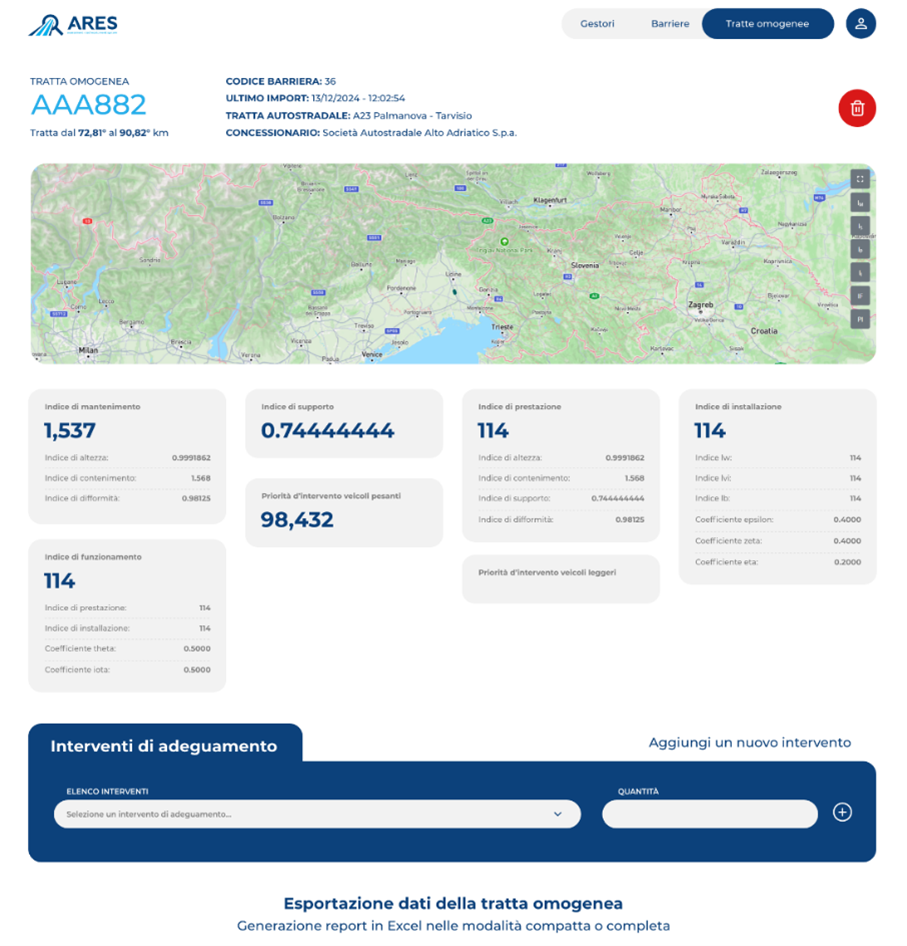

The WebApp allows the operator to enter the adjustments necessary to make road restraint systems compliant and the relative cost of each adjustment. The cost index takes into account the fact that, for the same expenditure, it is preferable to intervene on longer, uniform sections of road, considering the greater probability that these may be involved in accidents.

Using a database containing the main adjustments and their unit prices, the operator can draw up a list of adjustments to be carried out within the WebApp, with the option of specifying the quantities for each adjustment; following this activity, the PI can be recalculated.